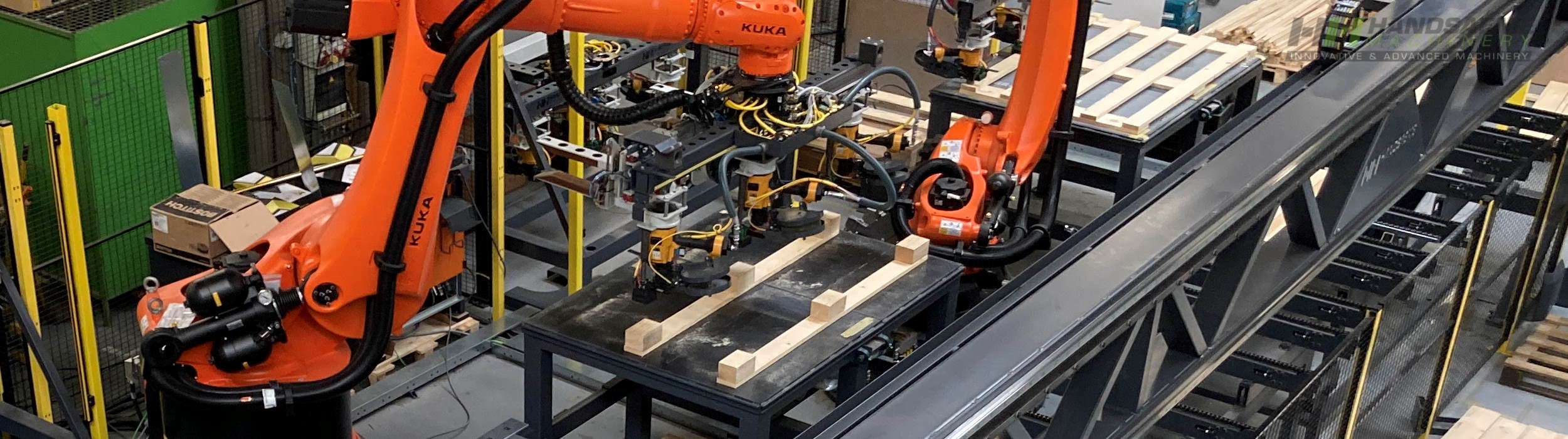

Autonomously and continuously assembling of complete pallets

The HM-ROB G2 is designed for continuous assembling

- Unique concept: pallet production without labour and jigs as the holding of the parts and the fastening is done with the same robot arm and in 1 time

- Patented solution for which we incorporated 3 KUKA robots

- Robot 1: bin picking with vision application

- Robot 2: makes ski’s, assembles the whole and evacuates the finished pallet

- Robot 3: makes the decks

- The only human action needed is to provide wood in the picking area and to remove the finished pallets

- The line is programmed to produce various types of wooden packing elements within the range of 500 x 500 and 1700 x 1200 mm.

- All tools are automatically positioned according to the chosen programming; so changing from one pallet type to another is done fully automatically in only a few minutes

↪ CAN BE USED TO MAKE PALLETS, CRATES AND GARDEN ELEMENTS.

➠ READ MORE ABOUT OUR ROBOT-SOLUTIONS |