Machine in the spotlight: Automated tufting creels

21/06/2023Automated tufting systems

Innovation

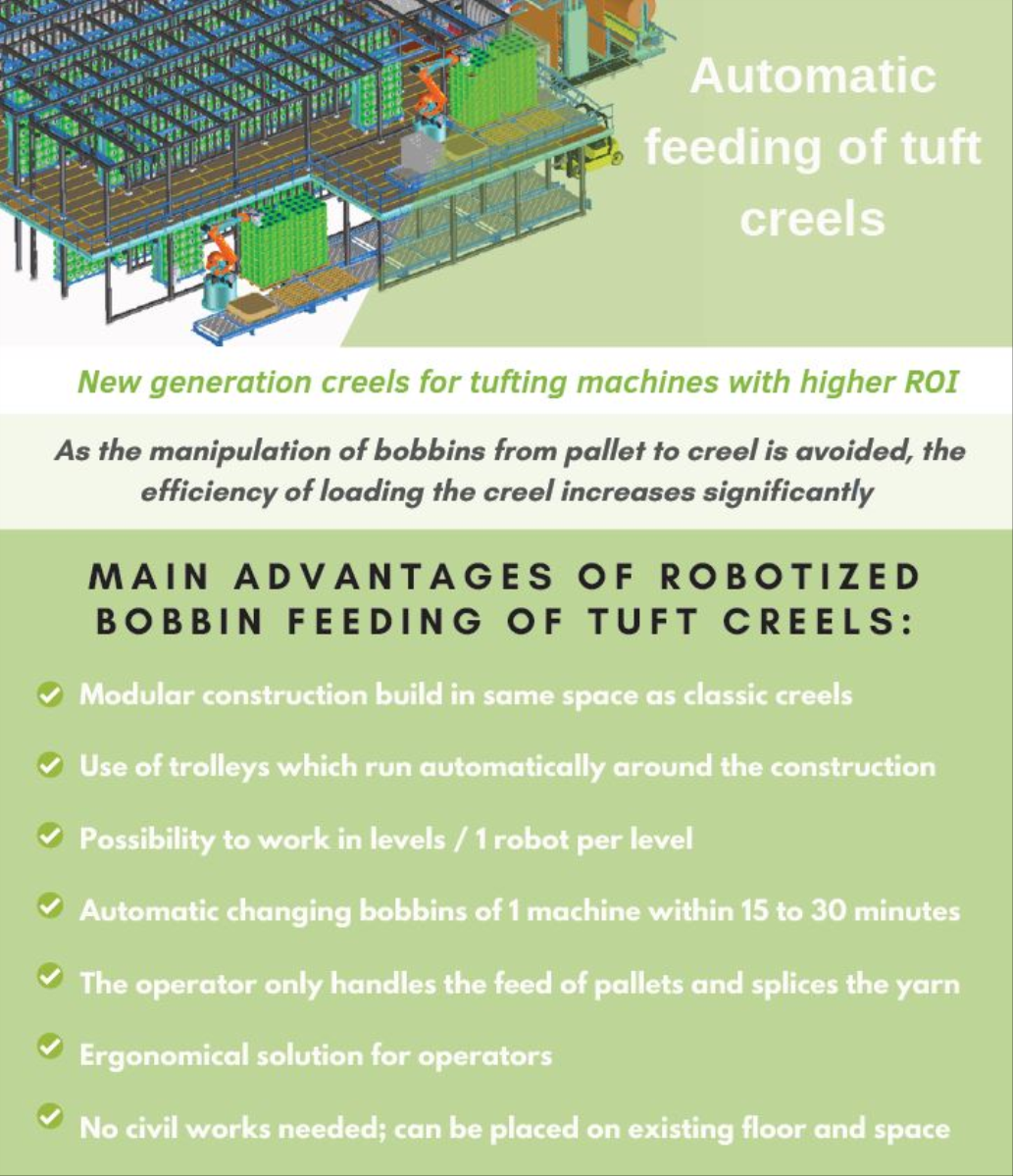

Our innovative concept for robotised bobbin feeding into the tuft rack ensures that producers of tufted carpets achieve a greater return on investment than traditional creel constructions. Because handling of the bobbins from pallet to trolley is avoided, loading efficiency is greatly increased. The operator only needs to load/unload complete pallets and splice the yarn so that he can perform other more productive tasks. The production efficiency and accuracy is considerably higher: depending on the number of bobbins to be changed, it can be done in 15 to 30 minutes.

“Automation provides greater efficiency and maintenance of local tufting industry”

Flexibility & customization

Within the same space of your current classic creels, we place new creels with automatic loading of the bobbins and that at high speed. For example, the bobbins are changed within approximately 20 minutes, which means that the downtime of the tufting machine is very limited. Larger bobbins can also be used because a robot lifts them onto the creels and operators can be used for other tasks that are not as stressful.

Safety & ease of use

The robot loads the bobbins from a pallet onto trolleys that automatically drive around the construction. The trains go in and out of the creels so that there is only one location where pallets need to be delivered and carried out, instead of an operator having to walk between the creels to reload, creating a safer and more ergonomic working environment. Due to increasing labor shortages and the reduction in the number of operators, this is a huge advantage to reduce personnel costs and still stay on the local market with production.

More info: https://www.handsaeme.be/en/carpet/machine/automated-tuft-creels

➠ CONTACT YOUR SALES ADVISOR FOR PERSONALISED INFO! |